Last week as well I finally got my fabric printed and steamed at UWE and the results were incredibly high quality. It was so exciting.

I brought it to the local upholstery that some friends own and talked about the possibilities of the fabric in relation with collaborating with the upholstery to create furniture and in relation with making small accessories having in mind the Christmas shopping season.

At the upholstery we measured the printed area and came up with the idea of making designer cushions that could be shown at the front of the shop for Christmas and making some pouches and pencil cases for my new etsy shop.

139×1 metre of fabric would give us:

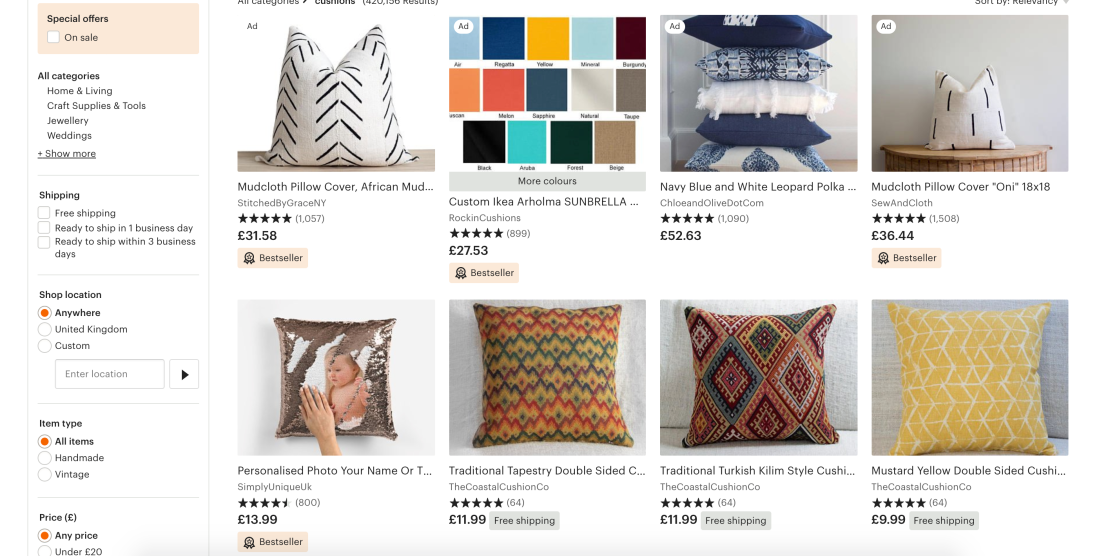

3-4 Cushions: we chose to use the design only in one side and use high quality velvet in the other side, plus a satin ribbon to frame the image that would give it a more luxurious look. The market price for alternative designer cushions is between 15 and 30 pounds. We decided to estimate a selling price of 20-25 + the price of the base cushion (5)

2-3 pencil cases: We would learn this together from scratch because the girls had only done furniture before but we easily found how to guides for it:

https://www.instructables.com/id/zippered-pencil-case/

We decided to give it a price of 15 pounds that is in the middle of prices in the market for this kind of exclusive pencilcase design.

2 cosmetic bags: They are slightly bigger in size but they have the same value in the market than pencilcases. We would follow same instructions than for the pencil cases except for the last steps so they would not be boxy but flat.

Having the fabric at a base cost of 25 pounds from uwe and not counting the hours of work invested we counted expenses and possible incomes:

25 printed fabric + 3 pounds of pink cotton for inside the pouches and 7 pounds of high quality black velvet + free zips provided by the upholstery+ 5 x 4 cushions = 55 pounds base cost.

possible incomes: 25 x 4 (cushions) + 15 x 4 (accesories)= 160 pounds.

Again before putting hands to work this seemed a very good learning process but not such a good deal for our time/economy.

To make it more exclusive we decided to order garment labels that we could add to the pieces. We tried to look for providers in Uk but prices were too high and the minimun order was always 500 labels. We looked for solutions in Asia, cheaper prices but a month of waiting not knowing the results. We are at the moment struggling to make a choice.

Next week we will start to sew and promote the products in Sns.